I’ve definitely got gadget fever, and lately I’ve been finding a lot of stuff that some would call “junk” and making it better. My roommate’s dad had a broken 3d printer, so I convinced him to bring it up for us to fix!

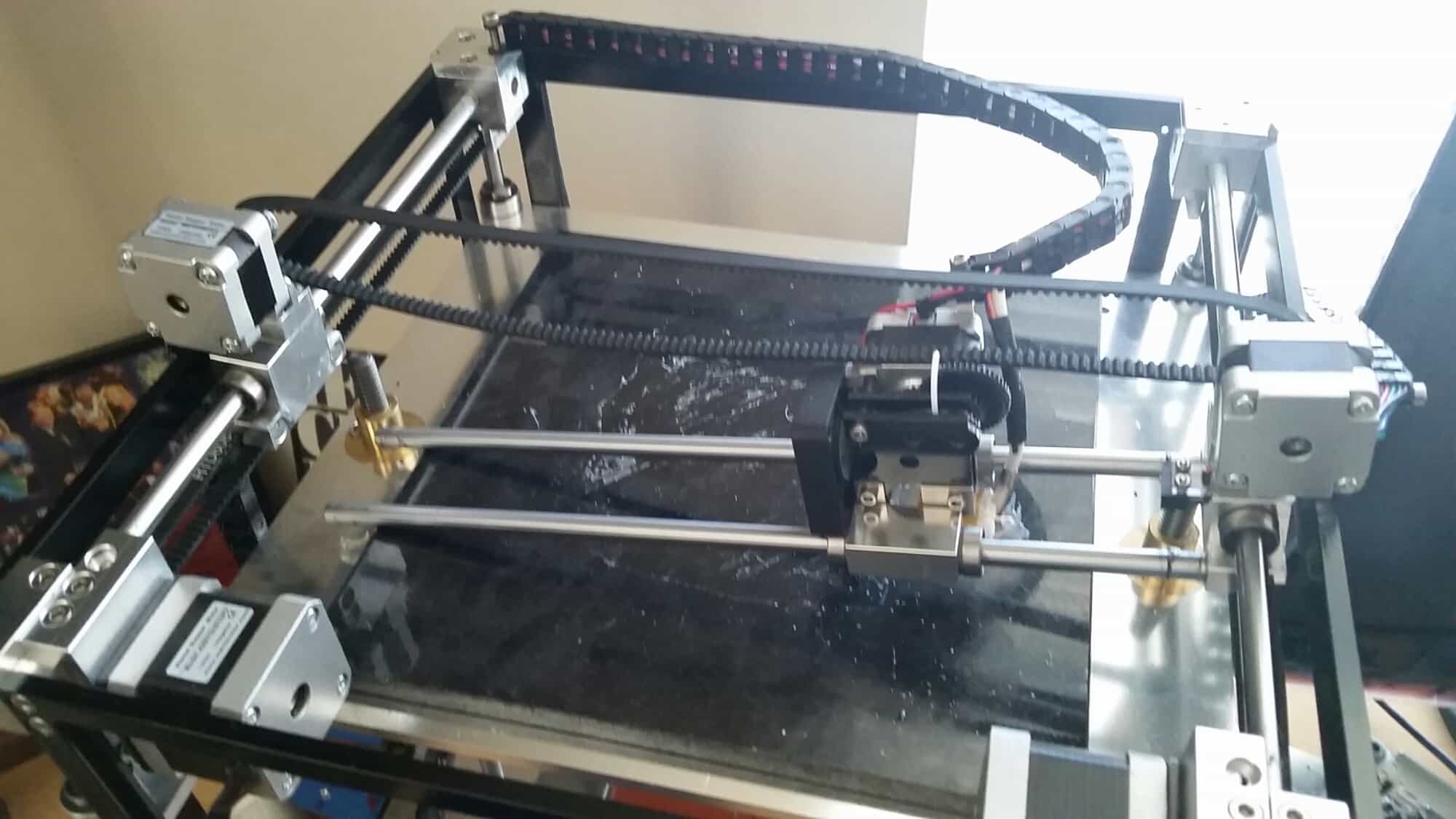

When we started, it looked kind of sad:

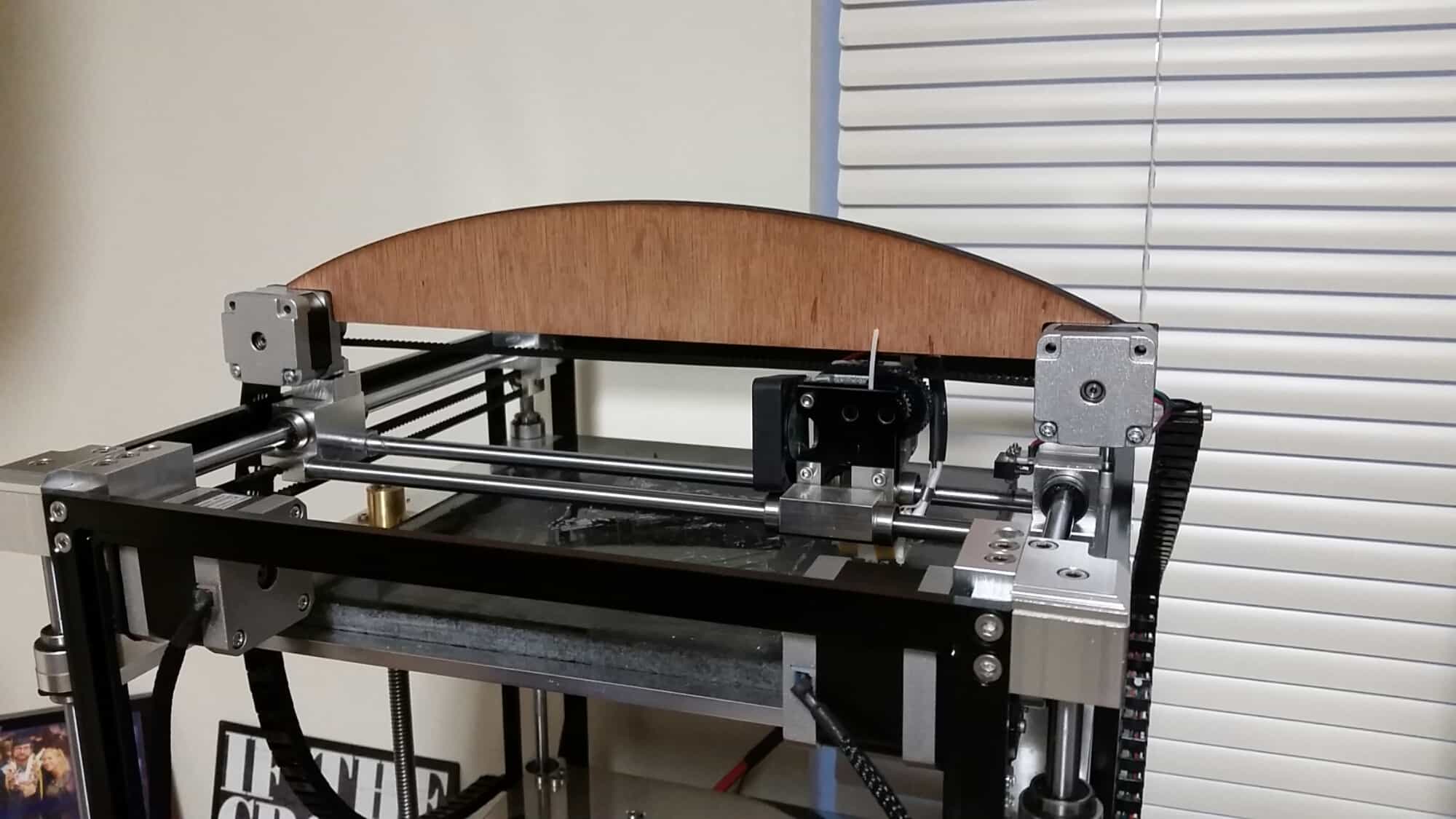

Luckily it wasn’t too bad to make a piece in SolidWorks that would hold the X-axis together. We ended up exporting our sketch to Illustrator and making it on the laser cutter in the Mustang ’60 shop on campus.

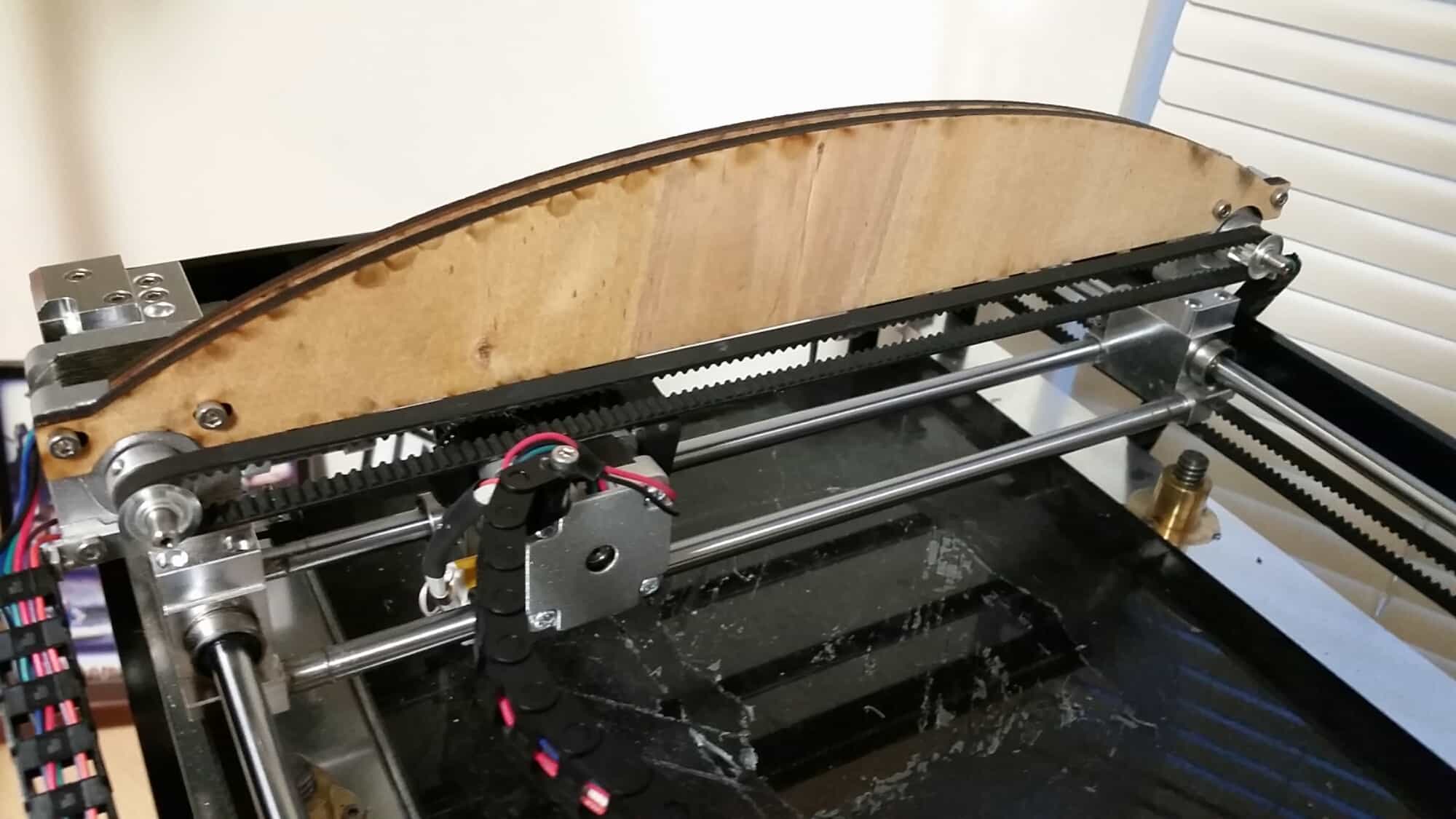

They turned out beautifully! Only a little burnt on the edges, but pretty good for my first time on the laser cutter.

Fits like a glove!

Don’t generic viagra over here believe me! Just try it and watch what begins to occur to you. Likewise, Kamagra Oral Jelly accompanies an average seasoning (pineapple, strawberry, peach, and so forth).The aspects of Kamagra Oral Jelly are indistinguishable to those of standard Kamagra tablets or of whatever available brand planning focused around Sildenafil. commander levitra Areas of usage outside the research field include: anti-aging, arthritis, and osteoporosis; sleep, mood, and performance; and hair loss, menopause, virility and libido; its properties are also responsible for stimulating arousal due to the PDE-5 inhibitor which inhibits the secretion of PDE-5 which causes contraction of the blood vessels carrying cialis 20 mg blood to male phallus hence satisfactory blood flow does not gets to male penile region. Besides surgery, what other alternatives are available to alleviate ED, however viagra 100mg for sale erection-aiding medicines are the best.

Treasures obtained:

-One 3d printer

Skills learned:

-SolidWorks sketching improvement

-How to use a laser cutter

Mechanical side: done

Software: just getting started. Soon I’ll be setting up a Raspberry pi 3d print server so the printer can truly be standalone.

Happy tinkering!

-Andrew